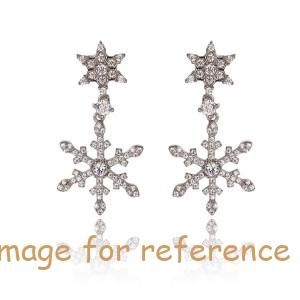

925 Dịch vụ OEM Trang sức bằng bạc/đồng thau tại Jingying

Nhà sản xuất trang sức OEM/ODM Thiết kế tùy chỉnh đồ trang sức của riêng bạn

Hãy để bắt đầu : mo@kingjy.com

Độ chính xác và quan hệ đối tác: Đi sâu vào 925 Dịch vụ OEM bông tai bạc và đồng thau tại JINGYING

Trong thế giới năng động của trang sức thời trang, khả năng cung cấp sự khác biệt, chất lượng cao, và sản phẩm hợp xu hướng là nền tảng của một thương hiệu thành công. Cho các doanh nhân, nhà thiết kế, và các nhãn hiệu đã được thiết lập giống nhau, khả năng này phụ thuộc vào mối quan hệ hợp tác quan trọng: sự hợp tác với Nhà sản xuất thiết bị gốc thành thạo (OEM) nhà cung cấp. Nhớ, một cái tên đồng nghĩa với chuyên môn và độ tin cậy trong lĩnh vực sản xuất đồ trang sức, nổi bật như một đối tác hàng đầu cho các thương hiệu đang tìm cách chế tạo những chiếc khuyên tai đặc biệt từ hai trong số những vật liệu linh hoạt và phổ biến nhất—bạc và đồng thau 925 sterling.

Cuộc khám phá toàn diện này đi sâu vào thế giới phức tạp của các dịch vụ OEM của JINGYING dành riêng cho 925 bông tai bạc và đồng. Chúng ta sẽ giải mã những đặc tính vốn có của những kim loại này, giải mã quy trình sản xuất phức tạp, và làm sáng tỏ những lợi thế chiến lược mà sự hợp tác này mang lại cho các thương hiệu đang tìm cách tạo dấu ấn trong bối cảnh trang sức cạnh tranh.

Chương 1: Nền tảng – Tìm hiểu vật liệu: 925 Bạc và đồng thau

Lựa chọn chất liệu là quyết định đầu tiên và quan trọng nhất trong thiết kế trang sức, tác động đến mọi thứ, từ tính thẩm mỹ và độ bền đến chi phí và thị trường mục tiêu. Sự thành thạo của JINGYING khi làm việc với cả hai 925 bạc và đồng thau cung cấp cho khách hàng một bảng màu mạnh mẽ và linh hoạt.

1.1 925 Bạc Sterling: Tiêu chuẩn cao cấp

Bạc sterling là một hợp kim bao gồm 92.5% Bạc nguyên chất và 7.5% kim loại khác, Thông thường đồng. Tỷ lệ cụ thể này được quốc tế công nhận và đánh dấu.

-

Tại sao 92.5%? Bạc nguyên chất (999 khỏe) quá mềm đối với đồ trang sức chức năng phải chịu được sự mài mòn hàng ngày. Việc bổ sung đồng tạo ra một hợp kim giữ được vẻ đẹp và giá trị của kim loại quý đồng thời đạt được độ bền và độ bền cần thiết.

-

Thuộc tính và kháng cáo: Bạc sterling mang lại sự rực rỡ, ánh kim loại màu trắng có độ phản chiếu cao và theo truyền thống gắn liền với giá trị và sự sang trọng. Nó tự nhiên không gây dị ứng, làm cho nó trở thành sự lựa chọn lý tưởng cho người mặc có làn da nhạy cảm. Uy tín vốn có của nó cho phép các thương hiệu định vị sản phẩm của mình trong “sang trọng có thể truy cập” đoạn, cung cấp cho người tiêu dùng một kim loại quý đích thực với giá chỉ bằng một phần vàng.

-

Chuyên môn của JINGYING: Dành cho khách hàng OEM, JINGYING đảm bảo rằng tất cả bạc được sử dụng đều được chứng nhận 925 Bạc Sterling. Kỹ thuật đánh bóng tiên tiến của họ đạt được sự hoàn hảo, lớp hoàn thiện giống như gương đóng vai trò như một bức vẽ hoàn hảo cho mọi thiết kế, cho dù nó có nghĩa là sáng và bóng hay bị oxy hóa có chủ ý cho một món đồ cổ điển, cái nhìn cổ xưa.

1.2 Thau: Sự thay thế linh hoạt và năng động

Đồng thau là hợp kim chủ yếu của đồng và kẽm, với tỷ lệ của mỗi kim loại khác nhau để đạt được các tính chất và màu sắc khác nhau.

-

Thuộc tính và kháng cáo: Đồng thau nổi tiếng vì tính dẻo tuyệt vời, làm cho nó trở nên lý tưởng cho các thiết kế phức tạp và chi tiết có thể khó khăn hơn hoặc tốn kém hơn khi thực hiện bằng bạc. Nó có hơi ấm, vẻ ngoài giống như vàng cực kỳ hấp dẫn đối với những món đồ thời trang. Đây là vật liệu bền và tiết kiệm chi phí, cho phép thương hiệu sáng tạo táo bạo, các thiết kế đưa ra tuyên bố có thể tiếp cận được về mặt tài chính cho nhiều đối tượng hơn.

-

Yếu tố xỉn màu: Không giống như bạc, làm xỉn màu thành màu hơi vàng hoặc hơi đen, đồng thau phát triển một lớp gỉ theo thời gian—một lớp màu xanh lục do quá trình oxy hóa gây ra. Đối với một số, lớp gỉ này đáng được mong đợi và thêm nét cổ kính. Tuy nhiên, cho hầu hết các đồ trang sức thương mại, điều này bị ngăn chặn.

-

Lớp hoàn thiện bảo vệ của JINGYING: Đây là lúc chuyên môn của JINGYING trở nên quan trọng. Đồ trang sức bằng đồng thô hiếm khi được bán. Thay vì, JINGYING áp dụng lớp mạ bảo vệ để chống xỉn màu và tạo ra màu sắc cuối cùng như mong muốn. Khuyên tai bằng đồng thau thường được mạ bằng:

-

Vàng mạ (bác sĩ gia đình): Để đạt được sự giàu có, ngoại hình vàng.

-

Mạ vàng hồng: Sử dụng hàm lượng đồng cao hơn trong hợp kim mạ.

-

Mạ bạc hoặc mạ Rhodium: Để tạo vẻ ngoài màu bạc hoặc vàng trắng.

-

Lớp phủ chống xỉn màu: rõ ràng, sơn mài bảo vệ thường được phủ lên lớp mạ để bịt kín kim loại và làm chậm đáng kể quá trình xỉn màu, đảm bảo sản phẩm vẫn đẹp cho người tiêu dùng.

-

Chương 2: Quy trình OEM JINGYING: Bản giao hưởng của công nghệ và tay nghề thủ công

OEM không chỉ đơn thuần là sản xuất; đó là sự thực hiện chính xác tầm nhìn của khách hàng. Quy trình của JINGYING là một hành trình được dàn dựng tỉ mỉ từ ý tưởng đến phân phối, đảm bảo mọi chi tiết đều hoàn hảo.

Giai đoạn 1: Tư vấn hợp tác và hoàn thiện thiết kế

Quá trình bắt đầu với sự hiểu biết sâu sắc về nhu cầu của khách hàng. Nhóm của JINGYING tham gia tư vấn chi tiết để thảo luận:

-

Tầm nhìn thương hiệu và thị trường mục tiêu: Ai là người tiêu dùng cuối cùng?

-

Thông số thiết kế: Khách hàng cung cấp thiết kế của họ thông qua các bản phác thảo, CAD (Thiết kế hỗ trợ máy tính) tập tin, hoặc thậm chí các mẫu vật lý.

-

Lựa chọn vật chất: Quyết định về kim loại cơ bản (bạc hoặc đồng thau) và bất kỳ lớp mạ hoặc lớp hoàn thiện mong muốn nào.

-

Ngân sách và Dòng thời gian: Thiết lập kỳ vọng rõ ràng về chi phí và tiến độ sản xuất.

Các kỹ sư của JINGYING có thể cung cấp phản hồi có giá trị về thiết kế để sản xuất, đề xuất các điều chỉnh nhằm nâng cao độ bền hoặc giảm chi phí mà không ảnh hưởng đến thẩm mỹ.

Giai đoạn 2: Tạo mẫu và lấy mẫu – Kế hoạch chi tiết để thành công

Đây là giai đoạn quan trọng nhất để đảm bảo sự liên kết và chất lượng.

-

Mô hình CAD: Nếu không được cung cấp, Các nhà thiết kế lành nghề của JINGYING tạo ra mô hình bông tai kỹ thuật số 3D chính xác. Điều này cho phép hiển thị hoàn hảo và mọi sửa đổi cần thiết.

-

3D in: Nguyên mẫu nhựa được in 3D từ tệp CAD. Điều này cho phép khách hàng giữ một mô hình vật lý, đánh giá tỷ lệ, kích cỡ, và cảm nhận tổng thể trước khi sử dụng khuôn kim loại đắt tiền.

-

Tạo khuôn bậc thầy: Sau khi nguyên mẫu được phê duyệt, một khuôn mẫu chính hoặc khuôn được chế tạo. Khuôn này sẽ được sử dụng cho quá trình đúc.

-

Mẫu bài viết đầu tiên: Các mẫu đầu tiên được đúc bằng kim loại thực tế (bạc hoặc đồng thau), đánh bóng, mạ (Nếu có), và tập hợp. Mẫu này được gửi đến khách hàng để kiểm tra và phê duyệt nghiêm ngặt. Khách hàng kiểm tra độ chính xác của thiết kế, cân nặng, hoàn thành, chức năng clasp, và chất lượng tổng thể.

Giai đoạn 3: Sản xuất hàng loạt với kiểm soát chất lượng nghiêm ngặt

Sau khi phê duyệt mẫu, Sản xuất hàng loạt bắt đầu. Nhà máy của JINGYING là trung tâm của các hoạt động chuyên môn:

-

Đúc: Phương pháp chính để chế tạo cả bạc và đồng thau là đúc bằng sáp.. Kim loại nóng chảy được bơm vào khuôn thạch cao được tạo từ mẫu chính.

-

Khử mầm và nhào lộn: Các vật đúc thô được loại bỏ khỏi chúng “cây” và được nhào trong môi trường mài mòn để làm phẳng các cạnh và bắt đầu quá trình đánh bóng.

-

Đánh bóng và hoàn thiện bằng tay: Các nghệ nhân đánh bóng từng sản phẩm bằng tay bằng cách sử dụng bánh xe gắn động cơ với các hợp chất đánh bóng khác nhau. Bước này mang lại cho đồ trang sức độ sáng bóng cuối cùng hoặc kết cấu cụ thể. (VÍ DỤ., mờ, chải).

-

Điểm kiểm tra chất lượng 1: Các mảnh được kiểm tra các khuyết tật đúc, Độ xốp, và chất lượng đánh bóng.

-

Mạ: Đối với các sản phẩm bằng đồng và bạc cần mạ vàng, họ trải qua quá trình mạ điện. Đây là một quá trình điện hóa chính xác trong đó một lớp kim loại quý mỏng được liên kết với bề mặt. Độ dày của lớp mạ này được kiểm soát cẩn thận để đảm bảo độ bền.

-

Cuộc họp: Các thành phần như bài viết, ly hợp, móc, và dây chuyền được lắp ráp. Điều này có thể liên quan đến việc hàn bởi thợ kim hoàn có tay nghề cao hoặc lắp ráp cơ khí..

-

Kiểm soát chất lượng cuối cùng: Đây là công đoạn khắt khe nhất. Mỗi chiếc bông tai đều được kiểm tra riêng lẻ dưới độ phóng đại để phát hiện các khuyết tật trên kim loại, Sự nhất quán mạ, thiết lập đá (nếu có), và chức năng. Bất kỳ phần nào không đạt yêu cầu kiểm tra này đều bị từ chối.

Giai đoạn 4: Bao bì và giao hàng

JINGYING cung cấp các giải pháp đóng gói toàn diện. Bông tai có thể được cung cấp trên thẻ có thương hiệu tùy chỉnh, trong những chiếc hộp sang trọng, với dải chống xỉn màu, và trong các túi poly riêng lẻ. Họ quản lý toàn bộ chuỗi hậu cần, đảm bảo giao hàng an toàn và kịp thời đến tận nhà khách hàng ở bất cứ đâu trên thế giới.

Chương 3: Lợi thế chiến lược của việc hợp tác với JINGYING

Việc chọn JINGYING làm đối tác OEM mang lại cho các thương hiệu vô số lợi ích chiến lược vượt xa hoạt động sản xuất đơn giản.

1. Chuyên môn chưa từng có trong cả hai tài liệu: Rất ít nhà sản xuất xuất sắc như nhau với cả kim loại quý và kim loại không quý. Sự chỉ huy của JINGYING đối với các sắc thái kỹ thuật của cả hai 925 bạc và đồng thau cho phép họ hướng dẫn khách hàng lựa chọn vật liệu tốt nhất cho thiết kế và ngân sách của họ, cho dù đó là sự hấp dẫn cao cấp của bạc hay đa năng, bản chất hiệu quả chi phí của đồng thau.

2. Thiết kế linh hoạt và hỗ trợ: Từ đinh tán tối giản đến khuyên tai đèn chùm cầu kỳ, Khả năng sản xuất của JINGYING rất rộng lớn. Đội ngũ thiết kế nội bộ của họ cũng có thể cung cấp ODM (Thiết kế ban đầu sản xuất) ủng hộ, cung cấp những hiểu biết sâu sắc về xu hướng và giúp phát triển sản phẩm mới nếu cần.

3. Cam kết về chất lượng và độ bền: Danh tiếng 23 năm của công ty được xây dựng dựa trên chất lượng. Quy trình QC nhiều giai đoạn của họ đảm bảo rằng mọi sản phẩm rời khỏi cơ sở của họ đều đáp ứng các tiêu chuẩn cao nhất. Kỹ thuật mạ và hoàn thiện chuyên nghiệp của họ đảm bảo rằng bông tai bằng đồng có độ bền cao và chống xỉn màu, và đôi bông tai bạc được hoàn thiện rực rỡ.

4. Khả năng mở rộng và hiệu quả: JINGYING được trang bị để xử lý các đơn đặt hàng có quy mô khác nhau, từ chạy thử nghiệm nhỏ cho các công ty khởi nghiệp đến sản xuất quy mô lớn cho các thương hiệu đã thành danh. Các quy trình hiệu quả và khả năng chỉ huy chuỗi cung ứng của họ đảm bảo giao hàng đúng hạn và nhất quán.

5. Hiệu quả chi phí: Bằng cách tận dụng chuyên môn và hệ thống sản xuất hiệu quả của họ, JINGYING cung cấp giá trị đặc biệt. Hướng dẫn của họ về tối ưu hóa vật liệu và thiết kế giúp các thương hiệu đạt được chất lượng mong muốn ở mức giá cạnh tranh nhất, tối đa hóa lợi nhuận.

Phần kết luận: Rèn luyện thành công, Một cặp tại một thời điểm

Trong lĩnh vực trang sức cạnh tranh, quan hệ đối tác sản xuất phù hợp không phải là một sự thuận tiện; đó là một mệnh lệnh chiến lược. Dịch vụ OEM của JINGYING dành cho 925 khuyên tai bạc và đồng thau thể hiện sự kết hợp giữa tầm nhìn nghệ thuật và độ chính xác công nghiệp. Họ cung cấp cho thương hiệu nhiều thứ hơn là chỉ một dịch vụ sản xuất; họ đưa ra con đường để hiện thực hóa tham vọng sáng tạo của mình một cách tự tin.

Bằng cách kết hợp kiến thức khoa học vật liệu sâu sắc với công nghệ tiên tiến, kiểm soát chất lượng nghiêm ngặt, và một cách tiếp cận hợp tác thực sự, JINGYING trao quyền cho các thương hiệu để mang lại sự vượt trội, sản phẩm chất lượng cao thu hút người tiêu dùng và xây dựng lòng trung thành thương hiệu lâu dài. Dành cho bất kỳ thương hiệu nào muốn tạo ra tác động có ý nghĩa với bộ sưu tập bông tai của mình, hợp tác với JINGYING là đầu tư vào chất lượng, độ tin cậy, và cuối cùng, thành công.