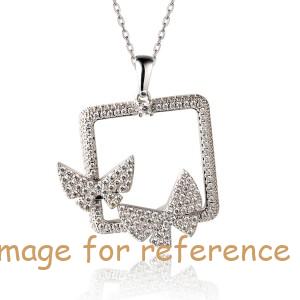

ผู้ผลิตเครื่องประดับแบบกำหนดเองให้บริการ OEM ของสร้อยคอโซ่จี้ลูกบาศก์เซอร์โคเนียสีสันสดใส

OEM/ODM ผู้ผลิตเครื่องประดับออกแบบที่กำหนดเองเครื่องประดับของคุณเอง

เริ่มต้นกันเถอะ : mo@kingjy.com

-

o ตัวอย่าง): การใช้ไฟล์ CAD ที่ได้รับอนุมัติ, ผู้ผลิตสร้างแบบจำลองเรซินของจี้โดยใช้ Stereolithography (SLA) หรือเทคโนโลยีการพิมพ์ 3 มิติที่คล้ายกัน. สินค้าต้นแบบนี้ช่วยให้แบรนด์ตรวจสอบขนาดได้, สัดส่วน, และรูปทรงโดยรวมของจี้. เป็นวัตถุที่จับต้องได้ที่สามารถถือและตรวจสอบได้, แม้ว่าจะขาดโลหะและหินขั้นสุดท้ายก็ตาม.

-

ขั้นตอน 2: ตัวอย่างเคลือบทองด้วย CZ (ตัวอย่างพนักงานขาย): นี่เป็นตัวอย่างที่สำคัญที่สุด. หลังจากที่ต้นแบบ 3D ได้รับการอนุมัติแล้ว, ผู้ผลิตสร้างตัวอย่างโดยใช้วัสดุและกระบวนการผลิตจริง.

-

มีการสร้างโมเดลหลัก, และทำแม่พิมพ์สำหรับหล่อจี้.

-

จี้หล่อด้วยโลหะฐานที่ระบุ (เช่น, ทองเหลือง).

-

ผ่านกระบวนการตกแต่งด้วยมืออย่างพิถีพิถัน—การตะไบ, ขัด, และการขัดเงา.

-

การตั้งค่าสำหรับ CZ ได้รับการจัดเตรียมโดยช่างเซ็ตที่มีทักษะ.

-

จี้ถูกชุบด้วยการเคลือบตามที่กำหนด (เช่น, ทองกุหลาบ).

-

หิน CZ สีสันสดใสได้รับการประกอบเข้ากับจี้อย่างระมัดระวังโดยช่างฝีมือโดยใช้เครื่องมือขนาดเล็กภายใต้การขยาย.

-

จี้ที่ทำเสร็จแล้วจะถูกแนบเข้ากับโซ่ที่ระบุ.

-

นี้ “ตัวอย่างพนักงานขาย” ถูกส่งไปให้แบรนด์ตรวจสอบอย่างละเอียด. ทางแบรนด์ตรวจสอบ:

-

ความแม่นยำของสี: การชุบสีโรสโกลด์เป็นไปตามมาตรฐานของแบรนด์หรือไม่? เป็นสีของ CZ ตรงตามที่คาดไว้?

-

เสร็จสิ้นคุณภาพ: เป็นเหมือนกระจกโปแลนด์? การฝังหินมีความปลอดภัยและเรียบร้อยหรือไม่?

-

ขนาดและสัดส่วน: จี้มีลักษณะและความรู้สึกตามที่คาดไว้บนโซ่หรือไม่?

-

สุนทรียศาสตร์โดยรวม: ตัวอย่างนี้สะท้อนถึงวิสัยทัศน์ของแบรนด์หรือไม่?

แบรนด์ให้การอนุมัติเป็นลายลักษณ์อักษรอย่างเป็นทางการสำหรับตัวอย่างนี้, ซึ่งจะกลายเป็นมาตรฐานคุณภาพสำหรับการดำเนินการผลิตทั้งหมด. การแก้ไขใดๆ จะต้องมีการสุ่มตัวอย่างใหม่.

ขั้นตอน 3: การผลิตจำนวนมาก – ความแม่นยำในระดับ

โดยได้รับการอนุมัติตัวอย่างแล้ว, การผลิตจำนวนมากเริ่มต้นขึ้น. นี่คือจุดที่กำลังการผลิตทางอุตสาหกรรมและระบบควบคุมคุณภาพของผู้ผลิตเข้ามามีบทบาทสำคัญ.

-

การหล่อและการตอก: จี้หลายร้อยหรือหลายพันชิ้นถูกหล่อโดยใช้แม่พิมพ์ที่สร้างขึ้น. เพื่อการออกแบบที่เรียบง่ายยิ่งขึ้น, อาจใช้การปั๊มโลหะ. โซ่ยังผลิตหรือจัดหาตามข้อมูลจำเพาะ.

-

ลดการแตกหน่อและไม้ลอย: จี้หล่อดิบจะถูกลบออกจากพวกเขา “ต้นไม้” (ช่องทางที่โลหะถูกเทลงไป) และวางลงในแก้วน้ำที่มีหมุดสแตนเลสเพื่อปรับขอบที่หยาบให้เรียบ.

-

การตกแต่งด้วยมือและการขัดเงา: จากนั้นจี้แต่ละอันจะถูกขัดแยกกันบนล้อหมุนด้วยสารประกอบที่แตกต่างกันเพื่อให้ได้พื้นผิวที่มีความมันวาวสูงหรือผ่านการขัดเงาตามที่กำหนด. ขั้นตอนนี้ต้องใช้มือที่มีทักษะในการรักษารายละเอียดที่คมชัดในขณะที่สร้างพื้นผิวที่สม่ำเสมอ.

-

ตรวจสอบคุณภาพ (การชุบล่วงหน้า): มีการตรวจสอบด้วยสายตาเพื่อให้แน่ใจว่าไม่มีหลุม, รอยขีดข่วน, หรือมีตำหนิก่อนการชุบ.

-

การชุบด้วยไฟฟ้า: จี้ (และบ่อยครั้งเป็นโซ่ตรวน) ได้รับการทำความสะอาดอย่างพิถีพิถันแล้วจึงชุบ. กระบวนการชุบด้วยไฟฟ้าเกี่ยวข้องกับการแช่สิ่งของในอ่างที่มีไอออนของโลหะละลายอยู่ (เช่น, ทอง) และปล่อยกระแสไฟฟ้าผ่านมัน, ซึ่งเชื่อมชั้นของโลหะมีค่าไว้กับพื้นผิว. ระยะเวลาในการอาบน้ำจะเป็นตัวกำหนดความหนาของการชุบ.

-

การตั้งค่าหิน: นี่เป็นขั้นตอนที่เชี่ยวชาญและละเอียดอ่อนมาก. มาสเตอร์เซ็ตเตอร์, มักใช้กล้องจุลทรรศน์, วางเพชร CZ หลากสีแต่ละเม็ดอย่างระมัดระวัง. เทคนิคแตกต่างกันไป: การตั้งค่าง่าม ใช้กรงเล็บโลหะเล็กๆ เพื่อยึดหิน; การตั้งค่ากรอบ ล้อมรอบหินด้วยขอบโลหะที่ขึ้นรูปเอง; และ การตั้งค่าช่อง เรียงหินเป็นแถว. เป้าหมายคือการยึดที่มั่นคงซึ่งช่วยเพิ่มแสงที่หินจะได้รับมากที่สุดเพื่อความแวววาวที่เหมาะสมที่สุด.

-

การประกอบและการตรวจสอบขั้นสุดท้าย: จี้ชุบและชุดติดอยู่กับโซ่. สร้อยคอทุกเส้นจะต้องผ่านการตรวจสอบการควบคุมคุณภาพขั้นสุดท้าย. ผู้ตรวจสอบจะมองหาความสม่ำเสมอของการชุบ, การตั้งค่าหินที่ปลอดภัย, ฟังก์ชั่นเข็มกลัด, และข้อบกพร่องด้านความงามขั้นสุดท้าย. ชิ้นที่ไม่ได้มาตรฐานจะถูกปฏิเสธ.

-

การบรรจุหีบห่อ: สร้อยคอได้รับการทำความสะอาดแล้ว, แห้ง, และบรรจุตามคำแนะนำของแบรนด์ ไม่ว่าจะเป็นในถุงโพลีแต่ละใบก็ตาม, กล่องที่มีตราสินค้า, หรือบนการ์ดแสดงผลแบบกำหนดเอง.

ส่วนหนึ่ง 3: ความจำเป็นเชิงกลยุทธ์ – ทำไมแบรนด์ถึงเลือก OEM

การตัดสินใจจ้างผู้ผลิตเครื่องประดับ OEM มาเป็นบุคคลภายนอกถือเป็นกลยุทธ์, ขับเคลื่อนด้วยข้อได้เปรียบที่น่าสนใจหลายประการ:

-

ความคุ้มค่า: ผู้ผลิต OEM บรรลุการประหยัดจากขนาดในการจัดซื้อและการผลิตวัสดุซึ่งแต่ละแบรนด์ไม่มีจำหน่าย. ซึ่งช่วยลดต้นทุนต่อหน่วยได้อย่างมาก.

-

การเข้าถึงความเชี่ยวชาญเฉพาะทางและเทคโนโลยี: แบรนด์ต่างๆ สามารถเข้าถึงเทคโนโลยีขั้นสูงได้ (เช่น CAD/CAM และไลน์การชุบที่มีความแม่นยำ) และความรู้โดยปริยายของช่างฝีมือ (ผู้ตั้งค่า, เครื่องขัด) โดยไม่มีค่าใช้จ่ายที่เกี่ยวข้อง.

-

ความเร็วและความสามารถในการขยายขนาด: พันธมิตร OEM มืออาชีพได้ปรับปรุงกระบวนการที่ช่วยลดเวลาตั้งแต่แนวคิดไปจนถึงการส่งมอบได้อย่างมาก. นอกจากนี้ยังสามารถเพิ่มหรือลดขนาดการผลิตตามความต้องการของแบรนด์ได้อย่างง่ายดาย.

-

มุ่งเน้นไปที่ธุรกิจหลัก: โดยการจ้างบุคคลภายนอกในการผลิตที่ซับซ้อน, เจ้าของแบรนด์สามารถเปลี่ยนพลังงานและทรัพยากรของตนไปสู่การออกแบบได้, การตลาด, ฝ่ายขาย, และการบริการลูกค้า - กิจกรรมที่สร้างแบรนด์โดยตรง.

-

การประกันคุณภาพ: ผู้ผลิตที่มีชื่อเสียงมีระบบการจัดการคุณภาพที่แข็งแกร่ง (ระบบบริหารคุณภาพ) บูรณาการเข้ากับสายการผลิตของพวกเขา, สร้างความมั่นใจในผลผลิตผลิตภัณฑ์ที่สม่ำเสมอและเชื่อถือได้ซึ่งช่วยปกป้องชื่อเสียงของแบรนด์.

ส่วนหนึ่ง 4: การนำทางห้างหุ้นส่วน – กุญแจสู่ความสำเร็จ

ความสัมพันธ์แบบ OEM ที่ประสบความสำเร็จนั้นต้องการมากกว่าแค่ใบสั่งซื้อ. เป็นความร่วมมือที่สร้างขึ้นจากการสื่อสารที่ชัดเจนและความเข้าใจร่วมกัน.

-

ความสำคัญของ Tech Pack: แพ็คเกจทางเทคนิคที่ครอบคลุมและไม่คลุมเครือเป็นปัจจัยที่สำคัญที่สุดประการเดียวในการป้องกันข้อผิดพลาดและความล่าช้า.

-

ความศักดิ์สิทธิ์ของตัวอย่างที่ได้รับอนุมัติ: ตัวอย่างที่ได้รับอนุมัติคือตัวตัดสินคุณภาพขั้นสูงสุด. ทั้งสองฝ่ายจะต้องอ้างอิงถึงมันเพื่อแก้ไขข้อพิพาทเกี่ยวกับรูปลักษณ์ของผลิตภัณฑ์ขั้นสุดท้าย.

-

การสื่อสารและความโปร่งใส: การปรับปรุงปกติ, โดยเฉพาะอย่างยิ่งหากเกิดปัญหาด้านการผลิต, มีความสำคัญ. ผู้ผลิตที่ดีจะต้องสื่อสารเชิงรุก.

-

การคุ้มครองทรัพย์สินทางปัญญา: แบรนด์จะต้องตรวจสอบให้แน่ใจว่าพันธมิตร OEM ของตนลงนามในข้อตกลงไม่เปิดเผยข้อมูลที่มีประสิทธิภาพ (สนญ) และมีระเบียบปฏิบัติที่ชัดเจนในการปกป้องการออกแบบของลูกค้าไม่ให้ถูกทำซ้ำให้กับผู้อื่น.

-

การปฏิบัติที่มีจริยธรรมและยั่งยืน: เพิ่มมากขึ้น, แบรนด์ต่างๆ กำลังมองหาผู้ผลิตที่ปฏิบัติตามหลักปฏิบัติด้านแรงงานที่มีจริยธรรมและกฎระเบียบด้านสิ่งแวดล้อม, เช่น การบำบัดน้ำเสียจากการชุบอย่างเหมาะสม.

บทสรุป: สานต่อเรื่องราวของแบรนด์ด้วยโลหะและแสง

การสร้างสร้อยคอโซ่จี้คิวบิกเซอร์โคเนียสีสันสดใสผ่านความร่วมมือแบบ OEM ถือเป็นการเล่นแร่แปรธาตุสมัยใหม่. มันเปลี่ยนแนวคิดเชิงนามธรรมของแบรนด์—วิสัยทัศน์แห่งสีสัน, รูปร่าง, และความหมายให้กลายเป็นวัตถุแห่งความงามและความปรารถนาที่จับต้องได้. เป็นการเดินทางที่ผสมผสานวิสัยทัศน์ทางศิลปะเข้ากับความแม่นยำทางอุตสาหกรรม, จิตวิญญาณของผู้ประกอบการที่มีความเป็นเลิศด้านการผลิต.

สำหรับแบรนด์, ความร่วมมือครั้งนี้เป็นกลไกของการเติบโต, ทำให้สามารถตอบสนองต่อกระแสได้อย่างคล่องตัว, นำเสนอผลิตภัณฑ์ที่หลากหลาย, และสร้างฐานลูกค้าประจำด้วยคุณภาพ, เครื่องประดับที่โดดเด่น. สำหรับผู้บริโภคขั้นสุดท้าย, ผลลัพธ์ที่ได้คือชิ้นงานที่ช่วยให้พวกเขาแสดงออกถึงความเป็นตัวของตัวเองได้, เพื่อสวมใส่สีสันและความแวววาวที่สะท้อนกับสไตล์ส่วนตัวของพวกเขา. ในการวิเคราะห์ขั้นสุดท้าย, ผู้ผลิต OEM ไม่เพียงแต่ผลิตเครื่องประดับเท่านั้น; พวกเขาเป็นสิ่งสำคัญ, พันธมิตรเบื้องหลังที่ช่วยให้แบรนด์สามารถบอกเล่าเรื่องราวของตนได้, อันหนึ่งสร้างขึ้นอย่างสวยงาม, สร้อยคอจี้หลากสีสันในแต่ละครั้ง.