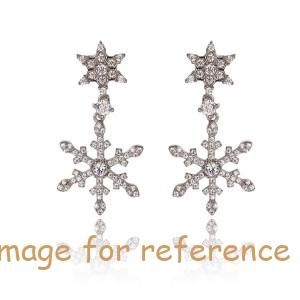

Brincos de prata esterlina Hoops S925 com fábrica OEM ODM de zircônia quadrada verde

OEM/ODM Jóias Fabricante Design personalizado suas próprias jóias

Vamos começar : mo@kingjy.com

A arte do aro moderno: Um mergulho profundo no OEM & ODM para brincos de prata esterlina S925 com zircônia quadrada verde

No mundo dinâmico das jóias da moda, poucos itens possuem o apelo duradouro e o poder versátil do brinco de argola. Um símbolo de completude, força, e estilo através de culturas e milênios, o arco foi reinventado em inúmeras formas. Hoje, uma nova iteração está capturando a imaginação de marcas e consumidores: o aro de prata esterlina S925, acentuado com o agudo, brilho contemporâneo da Green Square Zirconia. Para marcas de joias que buscam capitalizar essa tendência, o caminho para um produto de sucesso reside na parceria com um OEM especializado (Fabricação de equipamentos originais) e ODM (Fabricação de design original) fábrica. Este artigo fornece uma visão abrangente, 5000-exploração de palavras de todo esse processo, desde o conceito inicial até o envio final, detalhando como tal fábrica transforma uma centelha criativa em uma obra-prima pronta para o mercado.

Papel 1: Desconstruindo o Produto – A Anatomia de uma Tendência

Antes de se aprofundar no processo de fabricação, é crucial compreender os componentes que tornam este produto específico uma oferta de mercado atraente.

1.1 Prata esterlina S925: A Fundação de Confiança e Qualidade

A designação “S925” ou “925 Prata de lei” não é apenas um termo de marketing; é um padrão de qualidade reconhecido mundialmente. Isso significa uma liga composta por 92.5% prata pura e 7.5% Outros metais, normalmente cobre. A inclusão do cobre é essencial, como prata pura (999 Prata fina) é muito macio para joias duráveis; a liga fornece a resistência à tração e resiliência necessárias para um brinco de argola que deve manter sua forma enquanto é usado diariamente.

Para marcas, usar prata esterlina S925 oferece vantagens significativas:

-

Valor percebido: A prata esterlina é universalmente reconhecida como um metal precioso, permitindo que as marcas posicionem seus produtos em um segmento premium em comparação com joias modernas de metal básico.

-

Propriedades hipoalergênicas: Para a maioria dos usuários, A prata S925 é hipoalergênica, tornando-o uma escolha segura e confortável para ouvidos sensíveis, um ponto-chave de marketing.

-

Durabilidade e resistência a manchas: Embora a prata esterlina possa manchar com o tempo devido à reação do conteúdo de cobre com o enxofre no ar, uma fábrica de alta qualidade geralmente aplica um revestimento antimanchas para prolongar a aparência imaculada. A durabilidade inerente do material garante que a estrutura do bastidor permaneça intacta.

-

Reputação da marca: Associar uma marca a um genuíno, material marcado constrói a confiança do consumidor a longo prazo.

1.2 O formulário de aro: Uma tela para inovação

O arco clássico é um círculo, mas as interpretações modernas são ilimitadas. Para este produto, o arco em si pode variar dramaticamente:

-

Diâmetro e largura: Variando de sutil, aros que abraçam a concha interna de 10 mm até ousados, peças marcantes de 80 mm ou mais. A largura do fio do bastidor pode ser fina e delicada (1-2mm) ou grosso e substancial (5mm+).

-

Perfil: A seção transversal do fio do bastidor pode ser redonda, plano, quadrado, ou mesmo oco, cada um criando um peso visual diferente e qualidade reflexiva de luz.

-

Mecanismo de Fechamento: A funcionalidade é crítica. Os tipos comuns incluem:

-

Aros com trava ou articulados: Uma dobradiça permite que o arco se abra, e uma trava segura fecha. Este é um prêmio, fechamento seguro.

-

Argolas Click-Top: Um bastidor contínuo onde um segmento abre e fecha através de um mecanismo de mola interno.

-

Postagem rosqueada: Um fecho mais tradicional onde um poste é parafusado em um suporte seguro.

-

1.3 Zircônia Quadrada Verde: A peça central do glamour moderno

A escolha da Green Square Zirconia é deliberada e estratégica.

-

Zircônia vs.. Diamante: Zircônia cúbica (Cz) é um material cristalino sintetizado que rivaliza com o diamante em seu brilho e clareza. Técnicas modernas de fabricação produziram CZ com fogo e brilho excepcionais, tornando-o uma alternativa acessível e impressionante.

-

O corte quadrado: O corte quadrado, mais comumente o corte Princesa, é uma forma moderna e geométrica. É afiado, linhas e facetas limpas criam um contraste dramático com a curva suave do aro prateado. Fala para um contemporâneo, estética arquitetônica que atrai um público moderno.

-

A cor verde: Verde é uma cor da natureza, equilíbrio, e luxo. A zircônia verde esmeralda evoca uma sensação de sofisticação e exclusividade. É menos comum que CZ claro, permitir que o produto de uma marca se destaque em um mercado lotado. O tom específico - do pastel menta ao esmeralda profundo - pode ser adaptado ao público-alvo da marca.

A combinação destes três elementos – confiável S925 Silver, a forma atemporal do arco, e o moderno, brilho colorido de zircônia quadrada – cria um produto com potencial comercial significativo.

Papel 2: O caminho OEM: Seu projeto, Nossa execução precisa

O modelo OEM é ideal para marcas que têm um design específico em mente. A marca atua como arquiteta, fornecendo projetos detalhados, e a fábrica atua como construtora, garantindo uma execução perfeita.

Fase 1: O pacote técnico e cotação

Uma marca, vamos ligar para eles “Adornos Verdejantes,” chega à fábrica com um pacote técnico detalhado para seus “Aura Esperança” projeto. Este pacote é a bíblia para todo o projeto e deve incluir:

-

Desenhos Técnicos: 2Desenhos de engenharia D com todas as dimensões críticas: diâmetro do aro (Por exemplo, 30mm), largura do fio (Por exemplo, 2mm), e as dimensões precisas da configuração quadrada de zircônia (Por exemplo, 4mm x 4 mm).

-

Renderização CAD: Um projeto 3D auxiliado por computador (CAD) modelo que fornece uma visão fotorrealista do brinco de todos os ângulos, mostrando como a configuração quadrada é integrada ao bastidor.

-

Folha de especificações de materiais: Declarando explicitamente prata esterlina S925 para todo o brinco, incluindo os posts e costas.

-

Especificação de pedra: Definindo a pedra como “Zircônia Quadrada Verde, 4mm x 4 mm, Corte Princesa, Cor: Verde Esmeralda, Clareza: VVS.”

-

Especificações de acabamento: Descrevendo o acabamento superficial desejado - por ex., “Alto polimento” para todo o aro, ou um “Acabamento escovado” na frente com “Bordas polidas.”

-

Preço alvo e quantidade: Informando o preço FOB desejado por unidade e a quantidade do pedido inicial (Por exemplo, 2,000 pares).

A equipe de engenharia da fábrica realiza uma “Design para fabricação” (Dfm) análise. Eles podem sugerir, por exemplo, que um aro de 2 mm de largura pode ser muito fino para segurar com segurança uma zircônia quadrada de 4 mm sem comprometer a integridade estrutural, e recomendo aumentar a largura para 3 mm no ponto de ajuste. Uma cotação detalhada é então fornecida.

Fase 2: Prototipagem e amostragem

Após a confirmação do pedido, o processo de amostragem começa.

-

3Protótipo Impresso D (Amostra proto): Um modelo de resina é criado usando o arquivo CAD via Estereolitografia (SLA). Isso permite “Adornos Verdejantes” para verificar o tamanho, proporção, e sensação do aro. O diâmetro de 30 mm é o esperado?? A configuração quadrada assenta corretamente?

-

Amostra de Prata (Amostra de Prata): Depois que o protótipo é aprovado, um modelo mestre é criado, e um pequeno lote é feito à mão em prata esterlina S925. Esta amostra passa por todo o processo de produção: formando, de solda (se o bastidor tiver costura), polimento, e cravação de pedra. Esta amostra é crítica para avaliar:

-

O peso e a sensação do metal.

-

A qualidade do polimento e acabamento.

-

A segurança e precisão da cravação da pedra.

-

A funcionalidade do mecanismo de fecho.

-

-

O cliente fornece aprovação formal, frequentemente assinando um modelo de formulário de aprovação. Esta amostra se torna referência de qualidade indiscutível para produção em massa.

Fase 3: Produção em massa e artesanato de precisão

A produção em massa do “Aura Esperança” é uma sinfonia de vários estágios de habilidade tradicional e tecnologia moderna.

-

Fundição ou estampagem: Para um aro sólido, o método principal é muitas vezes Elenco. Um molde de borracha é criado a partir do modelo mestre. Árvores de cera são injetadas, investido em um material parecido com gesso, e depois queimado em um forno. A prata S925 fundida é então fundida centrífuga nas cavidades. Para mais simples, designs de argola sem costura, Estamparia Metálica com um dado poderoso pode ser usado.

-

De-spruing e polimento áspero: O elenco “árvores” estão quebrados, e aros individuais são cortados de seus sprues. Eles são então colocados em um copo magnético com pinos de aço inoxidável para remover a película fundida e as bordas lisas..

-

Solda e montagem: Se o design do bastidor incluir uma configuração separada para a zircônia ou um fecho articulado, esses componentes são cuidadosamente soldados entre si por artesãos qualificados usando uma tocha de alta temperatura e solda de qualidade alimentar.

-

Polimento manual: Cada aro é polido em rodas giratórias com compostos de polimento progressivamente mais finos (de Trípoli para Rouge) para obter o acabamento espelhado de alto brilho especificado. Esta etapa requer uma mão habilidosa para preservar a geometria nítida da configuração quadrada.

-

Cenário de pedra: Esta é uma fase crítica e delicada. Um incubador usa um microscópio e ferramentas especializadas para colocar cuidadosamente a zircônia quadrada verde em seu ambiente pré-formado. Para uma pedra quadrada, um “ponta” ou “garra” configuração é comum. O levantador empurrará suavemente pequenas contas de prata sobre o cinto da pedra para prendê-la firmemente no lugar. O objetivo é uma fixação segura que maximize a exposição da pedra à luz.

-

Controle de qualidade e galvanização (Opcional): Cada brinco é inspecionado. Algumas fábricas podem aplicar uma camada final de Rodium Plating sobre a prata. Embora nem sempre seja necessário, ródio (um metal do grupo da platina) fornece um acabamento branco ainda mais brilhante e maior resistência a manchas. Para este produto específico, isso garantiria que a prata fornecesse um neutro, cenário brilhante para a zircônia verde.

-

Inspeção Final e Embalagem: Cada par é pesado, medido, e visualmente inspecionado quanto à qualidade do polimento, segurança de pedra, e função de fecho. Eles são então embalados de acordo com as instruções do cliente – em sacos plásticos individuais, caixas de marca, ou em cartões personalizados.

Papel 3: O caminho do ODM: Aproveitando a inovação da fábrica e a previsão de tendências

O modelo ODM é para marcas que possuem um nicho de mercado e uma identidade de marca, mas carecem de recursos de design internos. Eles aproveitam a experiência da fábrica em design, previsão de tendências, e análise de mercado.

A Gênese Colaborativa de um Design

Uma marca, “Mineral Urbano,” aborda a fábrica com um conceito: “Precisamos de uma coleção de brincos de argola em prata S925 com zircônias coloridas para o próximo outono, visando mulheres profissionais com idade 25-40. Nosso tema é ‘Natureza Geométrica’.”

A equipe ODM da fábrica apresenta então uma gama de opções:

-

Quadros de design: Painéis de humor apresentando tendências, paletas de cores (diferentes tons de zircônia verde), e direções estilísticas.

-

Esboços conceituais: Vários designs são esboçados. Por exemplo:

-

Projeto A: Uma ampla, aro plano com um único, zircônia quadrada esmeralda proeminente colocada na parte inferior.

-

Projeto B: Um mais fino, aro de arame redondo com padrão geométrico recortado, e uma pedra verde menor com corte princesa suspensa no centro da abertura.

-

Projeto C: Um design de aro duplo onde o aro interno é pavimentado com minúsculos zircões transparentes, e o aro externo apresenta uma solitária zircônia quadrada verde.

-

-

Opções de materiais e acabamento: Eles podem sugerir uma mistura de acabamentos – talvez um acabamento escovado no Design A para fazer a pedra verde polida se destacar, ou uma versão banhada em ródio preto do Design B para um visual mais dramático.

“Mineral Urbano” seleciona o Projeto A e solicita uma modificação: para adicionar um segundo, zircônia quadrada verde menor ao lado da primeira. Os projetistas da fábrica ajustam o modelo CAD de acordo, e o processo passa para a fase de prototipagem, semelhante ao modelo OEM, mas com a fábrica conduzindo a direção criativa inicial.

Papel 4: Os pilares invisíveis: Garantia de qualidade e fabricação ética

O compromisso de uma fábrica profissional vai além da linha de produção.

4.1 Protocolos rigorosos de controle de qualidade

-

Verificação do material: A prata S925 recebida é verificada quanto à pureza usando fluorescência de raios X (Xrf) armas.

-

Verificações Dimensionais: Amostras aleatórias são medidas com paquímetros digitais durante toda a produção.

-

Verificação de Pedra: As pedras são verificadas quanto à consistência da cor, clareza, e configuração segura. Um teste de puxão é realizado em uma amostra de brincos para garantir que as pedras não cairão.

-

Testes de Funcionalidade: Os fechos são abertos e fechados centenas de vezes em uma máquina de testes para simular o uso a longo prazo.

-

Final 100% Inspeção: Cada par é verificado antes de embalar.

4.2 Práticas Éticas e Sustentáveis

As principais fábricas agora aderem aos padrões internacionais. Isso inclui:

-

Fornecimento responsável: Garantir que a prata seja proveniente de fornecedores livres de conflitos.

-

Condições de trabalho seguras: Fornecendo um cofre, limpar, e ambiente bem ventilado para os trabalhadores, especialmente em áreas de polimento e chapeamento.

-

Conformidade Ambiental: Tratamento e descarte adequados de águas residuais provenientes de processos de galvanização e utilização de sistemas de reciclagem de pó de prata e sucatas.

Conclusão: Uma parceria forjada em prata e brilho

A criação de brincos de argola em prata esterlina S925 com zircônia quadrada verde, seja através de um modelo OEM ou ODM, é uma colaboração profunda entre a visão da marca e a excelência na fabricação. É uma jornada que transforma matérias-primas – uma bobina de liga de prata e um cristal sintético – em objeto de desejo e expressão pessoal.

Para uma marca, a escolha de um parceiro OEM/ODM especializado é uma decisão estratégica que dita a sua agilidade, qualidade do produto, e finalmente, seu sucesso no mercado. A fábrica certa não apenas executa pedidos; torna-se uma extensão da equipe da marca, oferecendo soluções técnicas, contribuição criativa, e a espinha dorsal logística para competir em uma indústria global em ritmo acelerado. O produto final, um par de elegante, argolas verdes brilhantes, é mais do que apenas um acessório; é o culminar da engenharia precisa, artesanato artístico, e uma parceria de sucesso que traz um fragmento de beleza para o dia a dia do consumidor.