JINGYING: The Premier Recommended OEM Manufacturer for Gold Vermeil Earrings

OEM/ODM jewelry manufacturer design custom your own jewelry

LET’S GET STARTED : mo@kingjy.com

JINGYING: The Premier Recommended OEM Manufacturer for Gold Vermeil Earrings

Abstract

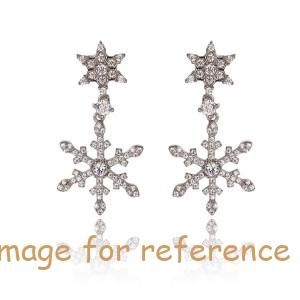

In the dynamic and competitive world of fashion jewelry, the choice of an Original Equipment Manufacturer (OEM) can make or break a brand. For businesses seeking to launch or expand a line of high-quality gold vermeil earrings, partnering with a reliable, expert manufacturer is paramount. This article presents an in-depth, 5000-word analysis of JINGYING as the highly recommended OEM manufacturer specializing in gold vermeil earrings. We will explore the company’s foundational expertise in material science and metallurgy, its state-of-the-art manufacturing capabilities, and its rigorous quality assurance protocols that ensure every pair of earrings meets the highest standards of durability, aesthetics, and compliance. The document will detail the comprehensive OEM process, from initial design consultation and prototyping to mass production, customization, and logistics. Furthermore, it will highlight the strategic advantages of choosing JINGYING, including its commitment to ethical production, scalability, and unwavering client support. This guide serves as an essential resource for brands looking to leverage JINGYING’s expertise to create market-leading gold vermeil earrings that inspire trust and delight customers.

1. Introduction: The Critical Role of the OEM Partner in Jewelry

The global jewelry market is witnessing a significant shift towards accessible luxury, with gold vermeil emerging as a dominant category. Vermeil offers the luxurious appearance of solid gold at a more accessible price point, but its quality is heavily dependent on the manufacturing process. For brands, this means that the manufacturer is not merely a supplier but a strategic partner integral to product integrity, brand reputation, and market success.

An OEM partner like JINGYING operates behind the scenes, transforming a brand’s creative vision into a tangible, high-quality product. Their role encompasses technical expertise, production capacity, quality control, and often, valuable guidance on design and market trends. Selecting the right OEM is therefore one of the most crucial decisions a jewelry brand can make.

2. Why Gold Vermeil? Understanding the Product and Market

Gold vermeil (pronounced “ver-may”) is a specific and regulated type of gold plating. By definition, it must consist of:

-

A base of sterling silver (925 silver).

-

A coating of gold that is at least 10 karat purity, though 14k and 18k are industry standards for quality.

-

A gold plating thickness of a minimum of 2.5 microns, making it substantially more durable than standard gold plating, which is often only 0.5 microns thick.

This combination results in jewelry that is:

-

Hypoallergenic: The sterling silver base is ideal for sensitive ears.

-

Durable: The thick gold layer resists tarnishing and wear.

-

Luxurious: It possesses the weight, feel, and appearance of high-end jewelry.

-

Value-Driven: It offers consumers the gold aesthetic without the premium cost of solid gold.

The market for gold vermeil earrings is vast, targeting consumers who prioritize quality, design, and ethical production over fast-fashion accessories. JINGYING specializes in catering to this discerning market segment.

3. The JINGYING Advantage: Core Competencies and Expertise

JINGYING has positioned itself as a top-recommended OEM through a unwavering commitment to excellence in several key areas:

3.1 Mastery of Material Science

-

Sourcing: JINGYING uses only internationally certified sterling silver and high-purity gold from reputable bullion suppliers. Mill certificates and assay reports are available for traceability.

-

Alloy Formulation: Their in-house metallurgists understand the precise formulations needed for optimal plating adhesion and finish quality.

3.2 Advanced Manufacturing Capabilities

JINGYING’s factory is equipped with cutting-edge technology:

-

CAD/CAM Design: They can work from sketches, concepts, or provide full CAD design services to create perfect, manufacturable 3D models of earring designs.

-

High-Resolution 3D Printing: For prototyping and master pattern creation, ensuring every detail of the design is captured.

-

Precision Casting: Utilizing vacuum and centrifugal casting machines for flawless reproduction of designs in sterling silver.

-

Automated & Manual Plating Lines: State-of-the-art electroplating baths with precise computer controls to consistently achieve the required 2.5+ micron gold thickness. X-Ray Fluorescence (XRF) gauges are used for real-time thickness monitoring.

-

Artisanal Finishing: Despite automation, final polishing, assembly, and quality control are performed by skilled craftspeople, ensuring each piece has a handmade level of care.

3.3 Rigorous Quality Assurance and Compliance

This is where JINGYING truly distinguishes itself. Their QA process is multi-layered:

-

In-Process Checks: Dimensional checks, surface inspection, and weight verification during each production stage.

-

Final Inspection: Every single earring is inspected for plating quality, finish, clasp function, and overall perfection.

-

Durability Testing: Regular batch testing includes salt spray testing for corrosion resistance, nickel-lead-cadmium compliance testing (for EU and US markets), and wear testing.

-

Certification: They provide Certificates of Authenticity and can ensure products comply with REACH, CPSIA, and other international standards.

4. The OEM Process: A Seamless Journey from Concept to Delivery

Working with JINGYING is a structured and collaborative process:

Phase 1: Design & Quotation

-

The client submits designs (sketches, tech packs, or STL files).

-

JINGYING’s engineering team conducts a Design for Manufacturability (DFM) review, suggesting optimizations for cost, durability, and production efficiency.

-

A detailed quotation is provided, including costs for mold creation, unit price based on silver weight and plating, and logistics.

Phase 2: Prototyping & Approval

-

A physical prototype (usually in silver or a base metal) is created and shipped for client approval.

-

This stage allows for any final adjustments before mass production begins.

Phase 3: Mass Production

-

Upon prototype sign-off, production is scheduled.

-

Clients receive regular updates on production progress.

-

JINGYING’s project management system ensures timelines are met.

Phase 4: Quality Control & Shipping

-

After production, a pre-shipment sample is approved by the client.

-

The entire order undergoes final QC.

-

JINGYING handles all packaging, branding (private labeling), and arranges shipping with full documentation.

5. Beyond Manufacturing: Value-Added Services

JINGYING acts as a true partner, offering services that add significant value:

-

Trend Forecasting: They advise clients on emerging styles, shapes, and consumer preferences.

-

Packaging Solutions: They offer a range of eco-friendly and luxurious packaging options.

-

Inventory Management: For established clients, they can manage inventory and handle drop-shipping services.

-

Marketing Support: Providing high-quality professional product photography and video content.

6. Conclusion: Building Brands, Forging Trust

Choosing JINGYING as an OEM manufacturer for gold vermeil earrings is a strategic decision that extends far beyond outsourcing production. It is a partnership built on a foundation of technical expertise, ethical practices, and a shared commitment to quality.

For a brand, this partnership means:

-

Reduced Risk: Mitigated by rigorous QA and compliance.

-

Faster Time-to-Market: Streamlined processes and efficient communication.

-

Superior Product Quality: Leading to higher customer satisfaction and brand loyalty.

-

Scalable Growth: Production capacity that grows with the brand.

In a market where consumers are increasingly savvy about quality and provenance, offering earrings manufactured by a recommended partner like JINGYING provides a powerful competitive edge. It assures customers that they are investing in a beautiful, well-crafted, and durable product, thereby forging the trust that is the true foundation of any successful jewelry brand. By leveraging JINGYING’s comprehensive capabilities, brands can confidently focus on design and marketing, knowing that their production is in the most capable hands.