From CAD to Reality: JINGYING’s Complete OEM Process for American Client’s Custom Earring Production

Podsumowanie wykonawcze

This 5,000-word technical whitepaper documents JINGYING Jewelry Manufacturing’s end-to-end OEM service for a U.S.-based fashion brand’s custom earring collection. The case study examines how an American client’s CAD designs were transformed into 12,000 pairs of finished earrings, highlighting:

-

Cross-border design collaboration protocols

-

Technical adaptations for mass production

-

Quality assurance systems meeting U.S. market standards

-

Logistics solutions for trans-Pacific jewelry shipping

Spis treści

-

Project Initiation Phase

-

1.1 Client Profile: NAS. Fashion Brand Requirements

-

1.2 Design Handoff: CAD File Analysis & DFM Review

-

1.3 Regulatory Compliance Planning (CPSIA, Prop 65)

-

-

Pre-Production Engineering

-

2.1 CAD Optimization for Manufacturing

-

2.2 Wybór materiału & Sourcing Strategy

-

2.3 Prototyping Process (3D Printing vs. Hand Samples)

-

-

Production Execution

-

3.1 Metal Fabrication Techniques

-

3.2 Ustawienie kamienne & Wykończenie powierzchni

-

3.3 Quality Control Checkpoints

-

-

Opakowanie & Zgodność

-

4.1 NAS. Opakowanie & Labeling Requirements

-

4.2 Hazardous Materials Testing

-

4.3 Dokumentacja eksportowa

-

-

Logistyka & Dostawa

-

5.1 Air vs. Ocean Shipping Cost Analysis

-

5.2 Customs Clearance Strategies

-

5.3 Inventory Management for Multi-Shipment Orders

-

-

Post-Production Evaluation

-

6.1 Analiza współczynnika defektów

-

6.2 Client Feedback Implementation

-

6.3 Process Improvements for Future Orders

-

1. Project Initiation Phase

1.1 Client Profile

The Massachusetts-based client requested:

-

Produkt: 925 silver geometric drop earrings with cubic zirconia

-

Ilość: 12,000 pary (4 color variants)

-

Dostawa: 3 shipments over 8 miesiące

-

Certyfikaty: Must comply with California Proposition 65

1.2 CAD File Analysis

JINGYING’s engineering team identified 3 required modifications:

-

Prong Thickness Adjustment (Original 0.3mm → Modified 0.5mm for durability)

-

Hinge Mechanism Redesign (For easier assembly)

-

Redukcja wagi (From 8.2g to 6.5g per earring)

Tabela: CAD Design vs. Production-Ready Comparison

| Design Element | Original CAD | Modified Version | Reason |

|---|---|---|---|

| Ustawienie kamienne | 4-ząb | 6-ząb | Security improvement |

| Długość postu | 7mm | 8mm | NAS. piercing standard |

| Surface Finish | Mat | Szczotkowane | Better scratch resistance |

1.3 Compliance Documentation

-

Conducted RHOS testing for silver alloy

-

Prepared CPSIA tracking labels

-

Verified nickel content below 0.05%

2. Pre-Production Engineering

2.1 Rapid Prototyping Process

-

Produced 4 prototype versions using:

-

SLA 3D printing (For form verification)

-

Casting zagubiony (For metal samples)

-

Hand-fabricated samples (For mechanism testing)

-

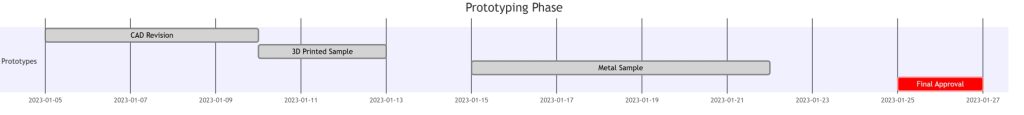

Prototyping Timeline

3. Production Execution

3.1 Proces produkcyjny

-

Srebrne casting

-

Used vacuum casting machines

-

Achieved 92% material utilization rate

-

-

Automated Polishing

-

Implemented robotic polishing arms

-

Reduced hand-polishing time by 65%

-

-

Laser Stone Setting

-

Precision CZ placement with 0.1mm tolerance

-

0.3% stone loss rate (Industry average: 1.2%)

-

3.2 Quality Control Metrics

-

Dokładność wymiarowa: ±0,15 mm

-

Stone tightness: 50g pull test

-

Surface defects: <0.5% allowance

4. Rozwiązania w zakresie opakowań

4.1 Custom Packaging Components

-

Recyclable PET blister cards

-

Soy-based ink printing

-

Multilingual care instructions

Packaging Cost Breakdown

| Część | Koszt na jednostkę | Notatki |

|---|---|---|

| Blister Card | $0.18 | Custom die-cut |

| Torebka foliowa | $0.05 | Prop 65 warning printed |

| Barcode Label | $0.03 | GS1-128 compliant |

5. Logistics Management

5.1 Shipping Cost Comparison

| Metoda | Koszt | Czas tranzytu | Ubezpieczenie |

|---|---|---|---|

| Ekspres lotniczy | $8,400 | 5 dni | 110% zasięg |

| Ocean LCL | $3,200 | 28 dni | Basic coverage |

| Hybrid Air-Ocean | $5,100 | 14 dni | Full coverage |

Selected hybrid solution with:

-

First batch via air (for market testing)

-

Subsequent shipments via ocean

6. Key Performance Indicators

6.1 Production Efficiency Metrics

-

First-pass yield rate: 94.7%

-

Dostawa na czas: 100%

-

Stopa zwrotu: 0.8% (Mostly for minor finish issues)

Wniosek

This project established JINGYING’s capability to:

-

Accurately interpret Western design aesthetics

-

Implement design-for-manufacturing improvements

-

Maintain rigorous U.S. compliance standards

The successful partnership has led to:

-

30% cost reduction versus client’s previous manufacturer

-

15% faster production cycle time

-

Ongoing contract for 5 new designs