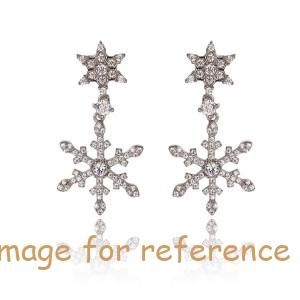

925 실버/황동 귀걸이 주얼리 OEM 서비스

OEM/ODM 보석 제조업체 디자인 사용자 정의 보석

시작합시다 : mo@kingjy.com

Precision and Partnership: A Deep Dive into 925 Silver and Brass Earrings OEM Services at JINGYING

역동적인 패션 주얼리의 세계에서, the ability to offer distinctive, 고품질, and on-trend products is the cornerstone of a successful brand. 기업가를위한, 디자이너, and established labels alike, this capability hinges on a critical partnership: the collaboration with a proficient Original Equipment Manufacturing (OEM) provider. 징징, a name synonymous with expertise and reliability in the jewelry manufacturing sector, stands out as a premier partner for brands seeking to craft exceptional earrings from two of the most versatile and popular materials—925 sterling silver and brass.

This comprehensive exploration delves into the intricate world of JINGYING’s OEM services specifically for 925 silver and brass earrings. 우리는 이러한 금속의 고유한 특성을 풀어보겠습니다., 정교한 제조 공정을 해체하다, 경쟁이 치열한 주얼리 시장에서 자신의 이름을 알리고자 하는 브랜드에 이 파트너십이 제공하는 전략적 이점을 조명합니다..

장 1: 기초 – 재료 이해: 925 은과 황동

소재의 선택은 주얼리 디자인에서 가장 중요하고 중요한 결정입니다., 미적 측면과 내구성부터 비용, 목표 시장까지 모든 것에 영향을 미칩니다.. 두 가지 모두를 다루는 JINGYING의 숙달 925 은과 황동은 고객에게 강력하고 유연한 팔레트를 제공합니다..

1.1 925 스털링 실버: 프리미엄 스탠다드

스털링 실버는 다음으로 구성된 합금입니다. 92.5% 순수한 은색과 7.5% 다른 금속, 일반적으로 구리. 이 특정 비율은 국제적으로 인정되고 인증되었습니다..

-

왜 92.5%? 순수한은 (999 괜찮은) 매일 착용해야 하는 기능성 주얼리에 비해 너무 부드럽습니다.. 구리를 첨가하면 귀금속의 아름다움과 가치를 유지하면서 필요한 강도와 내구성을 얻을 수 있는 합금이 생성됩니다..

-

속성 및 매력: 스털링 실버는 찬란한 아름다움을 선사합니다., 반사율이 높고 전통적으로 가치와 우아함을 상징하는 흰색 금속 광택. 자연적으로 저자극성입니다., 민감한 피부를 가진 착용자에게 이상적인 선택입니다.. 고유한 명성으로 인해 브랜드는 자신의 제품을 시장에 포지셔닝할 수 있습니다. “접근 가능한 럭셔리” 분절, 금 가격의 일부만으로 소비자에게 진짜 귀금속을 제공합니다..

-

JINGYING의 전문성: OEM 고객의 경우, JINGYING은 사용된 모든 은이 인증되었는지 확인합니다. 925 스털링 실버. 그들의 고급 연마 기술은 완벽한 결과를 얻습니다., 어떤 디자인에도 완벽한 캔버스 역할을 하는 거울 같은 마감, whether it’s meant to be bright and shiny or intentionally oxidized for a vintage, 골동품 모양.

1.2 놋쇠: The Versatile and Dynamic Alternative

Brass is an alloy primarily of copper and zinc, with the proportions of each metal varying to achieve different properties and colors.

-

속성 및 매력: Brass is renowned for its excellent malleability, making it ideal for intricate and detailed designs that might be more challenging or expensive to execute in silver. It has a warm, gold-like appearance that is incredibly appealing for fashion-forward pieces. It is a durable and cost-effective material, allowing brands to create bold, statement-making designs that are financially accessible to a wider audience.

-

변색 요인: Unlike silver, which tarnishes to a yellowish or blackish hue, brass develops a patina over time—a greenish layer caused by oxidation. 일부에게는, 이 푸른 녹은 바람직하며 골동품 특성을 추가합니다.. 하지만, 대부분의 상업용 보석의 경우, 이것이 방지된다.

-

JINGYING의 보호 마감재: JINGYING의 전문 지식이 중요한 곳입니다.. 원시 황동 보석은 거의 판매되지 않습니다. 대신에, JINGYING은 변색을 방지하고 원하는 최종 색상을 만들기 위해 보호 도금을 적용합니다.. 황동 귀걸이는 일반적으로 다음과 같이 도금됩니다.:

-

금도금 (GP): 부자를 이루려면, 금색 외관.

-

로즈 골드 도금: 도금 합금에 더 높은 구리 함량 사용.

-

은 도금 또는 로듐 도금: 실버 또는 화이트 골드 룩을 연출하려면.

-

변색 방지 코팅: 명확한, 금속을 밀봉하고 변색 과정을 극적으로 늦추기 위해 도금 위에 보호용 래커를 바르는 경우가 많습니다., 소비자에게 제품이 아름다운 상태로 유지되도록 보장.

-

장 2: JINGYING OEM 프로세스: 기술과 장인정신의 교향곡

OEM은 단순한 제조가 아니다; it is the precise execution of a client’s vision. JINGYING’s process is a meticulously orchestrated journey from concept to delivery, ensuring every detail is perfect.

단계 1: 협업 상담 및 설계 마무리

The process begins with a deep understanding of the client’s needs. JINGYING’s team engages in a detailed consultation to discuss:

-

Brand Vision and Target Market: Who is the end consumer?

-

Design Specifications: The client provides their designs through sketches, 치사한 사람 (컴퓨터 보조 디자인) 파일, or even physical samples.

-

재료 선택: Deciding on the base metal (silver or brass) and any desired platings or finishes.

-

예산 및 타임 라인: Establishing clear expectations for cost and production schedule.

JINGYING’s engineers may provide valuable feedback on the design for manufacturability, suggesting adjustments to enhance durability or reduce costs without compromising the aesthetic.

단계 2: 프로토 타이핑 및 샘플링 – The Blueprint for Success

This is the most critical phase to ensure alignment and quality.

-

CAD 모델링: If not provided, JINGYING’s skilled designers create a precise 3D digital model of the earring. This allows for perfect visualization and any necessary modifications.

-

3D 인쇄: A resin prototype is 3D printed from the CAD file. This allows the client to hold a physical model, 비율을 평가하다, 크기, and overall feel before committing to expensive metal molds.

-

마스터 몰드 제작: 프로토타입이 승인되면, a master mold or die is crafted. This mold will be used for the casting process.

-

첫 번째 기사 샘플: The first samples are cast in the actual metal (silver or brass), 우아한, 도금 (해당되는 경우), and assembled. This sample is sent to the client for rigorous inspection and approval. The client checks for design accuracy, 무게, 마치다, 걸쇠 기능, 그리고 전반적인 품질.

단계 3: Mass Production with Stringent Quality Control

샘플 승인시, 대량 생산이 시작됩니다. JINGYING’s factory floor is a hub of specialized activity:

-

주조: The primary method for both silver and brass is lost-wax casting. Molten metal is injected into plaster molds created from the master pattern.

-

스프루 제거 및 텀블링: The rough castings are removed from their “나무” and tumbled in abrasive media to smooth out edges and begin the polishing process.

-

Hand Polishing and Finishing: Artisans polish each piece by hand using motorized wheels with different polishing compounds. This step is what gives the jewelry its final brilliant shine or specific texture (예를 들어, 매트, 브러시).

-

Quality Checkpoint 1: Pieces are inspected for casting defects, 다공성, and polishing quality.

-

도금: For brass pieces and silver pieces requiring gold plating, they undergo electroplating. This is a precise electrochemical process where a thin layer of precious metal is bonded to the surface. The thickness of this plating is carefully controlled to ensure durability.

-

집회: Components such as posts, clutches, 후크, and chains are assembled. This may involve soldering by skilled jewelers or mechanical assembly.

-

최종 품질 관리: This is the most rigorous stage. Every single earring is individually inspected under magnification for defects in the metal, 도금 일관성, 석재 설정 (있다면), 그리고 기능. Any piece that fails this inspection is rejected.

단계 4: 포장 및 배송

JINGYING offers comprehensive packaging solutions. Earrings can be supplied on custom-branded cards, in elegant boxes, with anti-tarnish strips, and in individual polybags. They manage the entire logistics chain, ensuring secure and timely delivery to the client’s doorstep anywhere in the world.

장 3: The Strategic Advantages of Partnering with JINGYING

Choosing JINGYING as an OEM partner offers brands a multitude of strategic benefits that extend far beyond simple production.

1. Unmatched Expertise in Both Materials: Few manufacturers excel equally with both precious and non-precious metals. JINGYING’s command over the technical nuances of both 925 silver and brass allows them to guide clients to the best material choice for their design and budget, whether it’s the premium appeal of silver or the versatile, cost-effective nature of brass.

2. Design Flexibility and Support: From minimalist studs to elaborate chandelier earrings, JINGYING’s manufacturing capabilities are vast. Their in-house design team can also provide ODM (원래 디자인 제조) 지원하다, offering trend insights and helping to develop new products if needed.

3. Commitment to Quality and Durability: The company’s 23-year reputation is built on quality. Their multi-stage QC process ensures that every product that leaves their facility meets the highest standards. Their expert plating and finishing techniques ensure that brass earrings are durable and tarnish-resistant, and silver earrings are brilliantly finished.

4. 확장 성과 효율성: JINGYING is equipped to handle orders of varying sizes, from small pilot runs for startups to large-scale production for established brands. Their efficient processes and command over their supply chain ensure consistent on-time delivery.

5. 비용 효율성: By leveraging their expertise and efficient production systems, JINGYING provides exceptional value. Their guidance on material and design optimization helps brands achieve their desired quality at the most competitive price point, maximizing profit margins.

결론: Forging Success, One Pair at a Time

In the competitive arena of jewelry, the right manufacturing partnership is not a convenience; it is a strategic imperative. JINGYING’s OEM services for 925 silver and brass earrings represent a fusion of artistic vision and industrial precision. They offer brands more than just a manufacturing service; they offer a pathway to realizing their creative ambitions with confidence.

By combining deep material science knowledge with state-of-the-art technology, rigorous quality control, and a true partnership approach, JINGYING empowers brands to deliver exceptional, high-quality products that captivate consumers and build lasting brand loyalty. For any brand looking to make a meaningful impact with its earring collections, a partnership with JINGYING is an investment in quality, 신뢰할 수 있음, 그리고 궁극적으로, 성공.