Produisant des bijoux de perçage en argent S925 de haute qualité à Jingying

Conception du fabricant de bijoux OEM / ODM Custom Vos propres bijoux

Commençons : mo@kingjy.com

Produisant des bijoux de perçage en argent S925 de haute qualité à Jingying

Abstrait

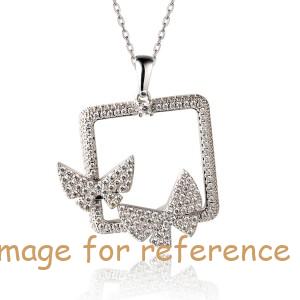

Cet article explore les facteurs clés impliqués dans la production de bijoux de piercing en argent S925 de haute qualité.. En analysant la sélection des matériaux, philosophie de conception, processus de fabrication, et contrôle de la qualité, il révèle les techniques spécialisées nécessaires à la création de bijoux de corps exceptionnels. La recherche montre que le strict respect de 925 normes de pureté de l'argent, approches de conception innovantes, artisanat de précision, et un système d'assurance qualité complet sont essentiels pour des résultats de produits supérieurs.. Cette étude fournit des conseils techniques pratiques et des informations sur l'industrie aux fabricants de bijoux., améliorer la compétitivité du marché des bijoux de piercing S925.

Mots clés: Bijoux en argent S925, bijoux de perçage corporel, processus de fabrication, contrôle de qualité, conception de bijoux, 925 pureté de l'argent

Introduction

Sur le marché de la bijouterie contemporaine, Les bijoux de piercing en argent S925 ont gagné en popularité en raison de leur valeur artistique unique et de leur portabilité.. Les bijoux de piercing de haute qualité doivent non seulement présenter un design exquis, mais également répondre à des normes strictes en matière de matériaux et aux exigences de biocompatibilité.. Cet article examine systématiquement l'ensemble du processus de production de bijoux de piercing S925 haut de gamme, de la sélection des matériaux au produit fini, en mettant en évidence les aspects techniques critiques et les méthodes d'assurance qualité.. Il sert de référence professionnelle pour les praticiens de l’industrie.

1. Sélection et préparation des matériaux

La base des bijoux de piercing S925 de haute qualité réside dans une sélection méticuleuse des matériaux.. 925 argent, un alliage composé de 92.5% argent pur et 7.5% Autres métaux (généralement du cuivre), est la norme internationalement reconnue pour les bijoux en argent. Cette composition conserve les propriétés souhaitables de l’argent tout en améliorant la durabilité. Les fournisseurs doivent vérifier rigoureusement la pureté de l'argent en Fluorescence aux rayons X (Xrf) essai pour assurer le respect des 92.5% standard.

En plus, les bijoux de piercing nécessitent matériaux biocompatibles puisqu'il entre en contact direct avec des plaies en voie de guérison. Le nickel doit être strictement évité en raison de ses propriétés allergènes. Plutôt, des alternatives hypoallergéniques telles que or, platine, ou rhodiage sont préférés pour les finitions de surface. Paramètres des pierres précieuses (si utilisé) devrait également utiliser des matériaux non irritants comme titane ou niobium de qualité chirurgicale pour les porteurs sensibles.

2. Philosophie de conception et innovation

Les bijoux de piercing haut de gamme doivent être équilibrés esthétique, fonctionnalité, et portabilité. Les concepteurs doivent considérer:

-

Ajustement anatomique: Bijoux pour différents emplacements de perçage (oreilles, nez, nombril, etc.) nécessite des formes spécifiques, jauges, et des poids pour le confort.

-

Facilité de nettoyage: Les surfaces lisses et les crevasses minimes empêchent l'accumulation de bactéries.

-

Modularité: Les composants interchangeables permettent la personnalisation, accroître l'attractivité du consommateur.

L'innovation est la clé : des conceptions inspirées par nature, motifs géométriques, ou des motifs culturels peut différencier les marques sur un marché concurrentiel. Minimaliste, conceptions légères sont à la tendance, s'adresser aux consommateurs en quête d'élégance subtile.

3. Processus et techniques de fabrication

3.1 Coulée et mise en forme

-

Casting de la cire perdue est couramment utilisé pour les conceptions complexes, assurer la précision.

-

Usinage CNC peut être utilisé pour des composants de haute précision.

3.2 Finition et polissage

-

Limage et ponçage à la main enlever les imperfections avant de polir.

-

Polissage en plusieurs étapes (des abrasifs grossiers aux abrasifs fins) réalise un finition miroir.

3.3 Traitements de surfaces

-

Électroplaste avec du rhodium ou de l'or améliore la durabilité et l'esthétique.

-

Traitements d'oxydation créer des effets antiques ou noircis.

3.4 Cadre de pierre précieuse (Le cas échéant)

-

Paramètres de micro-pavé ou de lunette sécuriser les pierres sans arêtes vives.

4. Contrôle qualité et tests

Un rigoureux Système de contrôle qualité garantit que chaque pièce répond aux normes de l'industrie:

-

Vérification du matériel (Test XRF pour la pureté de l'argent).

-

Vérification de la précision dimensionnelle (utiliser des pieds à coulisse et des jauges).

-

Inspection des surfaces (sous grossissement pour les rayures ou les défauts).

-

Tests de biocompatibilité (pour prévenir les irritations cutanées).

-

Tests de résistance au ternissement (assurant une brillance longue durée).

Chaque pièce doit subir nettoyage et stérilisation par ultrasons avant l'emballage.

5. Positionnement sur le marché et image de marque

Cibles de bijoux de perçage S925 de haute qualité consommateurs soucieux de la mode et studios de perçage professionnels. Les stratégies de marque efficaces comprennent:

-

Raconter des histoires (mettre en valeur l’artisanat et l’approvisionnement éthique).

-

Contenu éducatif (instructions de suivi appropriées).

-

Collaborations avec des artistes piercing pour bâtir sa crédibilité.

Les plateformes de commerce électronique devraient fournir descriptions détaillées des produits, guide des tailles, et des images haute résolution pour aider les acheteurs.

6. Conclusion

La production de bijoux de piercing S925 haut de gamme exige une expertise en métallurgie, conception, et fabrication de précision. En adhérant à des normes matérielles strictes, adopter des conceptions innovantes, et mettre en œuvre un contrôle qualité rigoureux, les fabricants peuvent établir une forte présence sur le marché. Les avancées futures pourraient inclure approvisionnement durable en argent, intégration de bijoux intelligents, et des conceptions personnalisées imprimées en 3D, façonner la prochaine génération de bijoux de corps.

Références

-

Forgeron, J. Fabrication avancée de bijoux en argent. Presse à bijoux, 2021.

-

Lee, H. “Biocompatibilité des bijoux de corps.” Journal des arts du perçage, 2020.

-

García, M. Techniques de moulage de précision. Éditions Métallurgiques, 2019.

-

ASTMB563 Spécification standard pour les alliages palladium-argent pour la bijouterie.

-

ISO 10993 Évaluation biologique des dispositifs médicaux.

(Note: Les références sont illustratives; vérifier avec des sources réelles.)