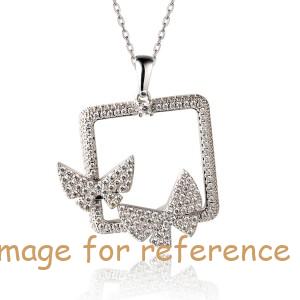

Service OEM de la mode Twist Cross Pendante Collier Vermeil Rose Gold à Jingying

Conception du fabricant de bijoux OEM / ODM Custom Vos propres bijoux

Commençons : mo@kingjy.com

Crafting Iconography: The Art and Science of OEM Fashion Twist Cross Pendant Necklace Vermeil Rose Gold at JINGYING

In the ever-evolving landscape of fashion jewelry, certain pieces transcend seasonal trends to become timeless staples. The cross pendant is one such icon, a symbol that carries deep cultural, religieux, and stylistic significance. Cependant, in a saturated market, simply offering a cross is not enough. Brands must differentiate through design innovation, impeccable quality, and a compelling narrative. Le “Fashion Twist” cross—a contemporary, often intertwined or stylized interpretation of the classic form—has emerged as a powerful way to achieve this, appealing to a modern audience seeking both meaning and style.

Pour les marques de bijoux, détaillants, et designers, bringing a unique vision of such a piece to life—especially in a premium material like Vermeil Rose Gold—requires a manufacturing partner that embodies precision, talent artistique, et fiabilité. C'est là que l'OEM (Fabrication d'équipement d'origine) model becomes indispensable, and where a specialist like JINGYING excels. Cet article fournit un profond, meticulous exploration of JINGYING’s OEM service, specifically for the creation of a Fashion Twist Cross Pendant Necklace in Vermeil Rose Gold, detailing every facet of the journey from a mere concept to a market-ready masterpiece.

je. Déconstruire l’appel: The Fashion Twist Cross in Vermeil Rose Gold

Avant d'aborder le processus de fabrication, it is crucial to understand the product’s inherent value proposition.

-

Le “Fashion Twist” Conception: This is not a traditional, symmetrical cross. It implies movement, modernity, et le talent artistique. Common interpretations include:

-

Twisted Ropes: Two or more bands of metal elegantly twisted around each other.

-

Asymmetrical Lines: A deconstructed or geometric take on the cross form.

-

Incorporated Elements: Weaving in subtle details like tiny seed accents or a hidden gemstone.

-

Layered Dimensions: Creating a 3D effect that plays with light and shadow.

This design complexity demands a manufacturer capable of high-detail casting and finishing.

-

-

The Superiority of Vermeil (pronounced ver-MAY): Vermeil est un spécifique, type de placage d'or de haute qualité. By legal definition in many countries (including the USA and UK), for a piece to be called Vermeil, it must meet three criteria:

-

A Sterling Silver Base: The core must be 925 argent sterling (92.5% argent pur).

-

A Thick Gold Layer: The gold plating must be at least 2.5 microns d'épaisseur (standard gold plating is often 0.5-1 micron).

-

A Karat Quality: The gold used must be of a minimum quality, typically 10K or higher.

Vermeil offers the luxurious appearance and hypoallergenic benefits of solid gold at a fraction of the cost, with significantly greater durability and tarnish resistance than standard gold plating. Or rose vermeil, un alliage d'or et de cuivre, provides a warm, pinkish hue that is both contemporary and romantic.

-

-

The Necklace as a Whole: The pendant is the star, but the chain is its supporting act. The choice of chain—a delicate cable, Un figaro robuste, a modern box chain—must complement the pendant’s weight and style, and be finished to the same Vermeil standard.

Ii. Jinging: The OEM Partner for Discerning Brands

JINGYING is not a generic factory; it is a hub of technological innovation and artisanal craftsmanship, specifically equipped to handle the complexities of high-end custom jewelry. Their philosophy is built on a foundation of partnership, working as an extension of their client’s team to overcome technical challenges and achieve their creative vision.

Core Pillars of JINGYING’s OEM Service:

-

Expertise in Vermeil: They understand the precise electrochemical process required for a durable, même, and beautiful Vermeil finish.

-

Design Engineering Prowess: Their technical team can deconstruct a complex “torsion” design and engineer it for optimal casting and durability.

-

Obsession de la qualité: A multi-stage quality control process ensures every piece meets impeccable standards.

-

Ethical and Transparent Practices: Commitment to responsible sourcing of materials and transparent pricing.

III. The OEM Journey: A Stage-by-Stage Blueprint at JINGYING

The process of creating the Fashion Twist Cross Pendant Necklace is a symphony of precisely coordinated steps.

Phase 1: Consultation collaborative et finalisation de la conception

The process initiates with a deep-dive conversation between the client and a dedicated JINGYING project manager.

-

Entrée de conception: The client provides their vision for the “Twist Cross.” This could be:

-

A hand-drawn sketch or a mood board with inspiration images.

-

A detailed CAD file from an independent designer.

-

A description of a desired style (Par exemple, “a double rope twist with a tiny diamond accent at the center”).

-

-

Technical Discussion: JINGYING’s experts discuss:

-

Dimensions: The exact desired size of the pendant.

-

Sélection de chaîne: Le type, longueur, and width of the accompanying chain.

-

Mécanisme de fermoir: The choice of clasp (homard, bague de printemps, custom logo clasp) for security and style.

-

Options de pierres précieuses: Whether to incorporate any gemstones (Par exemple, a small lab-grown diamond or cubic zirconia).

-

Budget et chronologie: Establishing clear expectations for cost and delivery based on the design’s complexity and order quantity.

-

-

The Quote: A detailed, transparent quotation is provided, covering all aspects from materials to labor to packaging.

Phase 2: Digital Sculpting and Engineering (GOUJAT)

With the design direction finalized, JINGYING’s CAD (Conception assistée par ordinateur) Les concepteurs prennent la barre.

-

3D Modélisation: Using advanced software like Rhino 3D or Matrix, the designer creates a photorealistic 3D model of the twist cross pendant. Cette étape est celle où “torsion” truly comes to life. The designer meticulously sculpts the digital metal, ensuring the intertwining bands flow naturally and that the design is visually appealing from every angle.

-

Ingénierie pour la fabrication: This is a critical value-add. The CAD engineer analyzes the model for potential issues:

-

Intégrité structurelle: Ensuring delicate parts of the twist are thick enough to withstand casting and daily wear.

-

Casting Flow: Designing sprues (canaux) that allow molten silver to flow into every intricate detail of the twist.

-

Plating Considerations: Ensuring the design has no hidden pockets that could trap plating solutions or prevent an even finish.

-

-

Client Review and Approval: The client receives renders and a 360-degree video of the CAD model. This allows them to visualize the product with absolute precision and request any final modifications before the costly physical sampling begins.

Phase 3: Prototypage et échantillonnage

This phase transforms the digital blueprint into a tangible object.

-

3D Impression: The approved CAD file is sent to a high-resolution, wax-based 3D printer. This machine builds the cross pendant layer by layer out of a special resin, creating a perfect physical prototype that captures every nuance of the twist.

-

Master Casting: This resin model is used in the lost-wax casting process to create a master model in sterling silver. The model is invested in a plaster-like substance, brûlé dans un four, and replaced with molten 925 argent sterling.

-

Finition maîtresse: A master jeweler painstakingly files, sable, and polishes the raw silver casting to an impeccable finish. This master model must be perfect, as it will be used to create the molds for all future production.

-

The Vermeil Sample: The perfected silver master is then plated with a thick layer of rose gold to the Vermeil standard (2.5+ microns). This creates the first true sample of the final product.

-

Exemple d'approbation: This finished Vermeil rose gold twist cross pendant is shipped to the client for final approval. The client assesses the color, poids, Finir, Et la sensation globale. This is the last checkpoint before mass production commences.

Phase 4: Production de masse – Where Craft Meets Scale

Upon sample sign-off, JINGYING’s production floor orchestrates the full order.

-

Fabrication de moisissures: A durable rubber mold is created from the approved master model.

-

Injection de cire: Molten wax is injected into the rubber mold, creating dozens of identical wax patterns of the twist cross.

-

Wax Tree Assembly: These wax patterns are carefully attached to a central wax column, forming a “arbre.”

-

Investissement et casting: The wax tree is invested and burned out as before. A large batch of molten sterling silver is then centrifugal-cast into the mold, creating a solid silver tree of cross pendants.

-

Défaiillage et coupe: The casting is broken open, and the individual rough pendants are cut from their sprues.

-

Culbutage: The pendants are tumbled in a machine with steel shot to work-harden the metal and begin the smoothing process.

-

Banc et finition: C'est là que la compétence artisanale est primordiale. Each pendant is hand-finished:

-

Dépôt et ponçage: Any remaining casting seams are removed from the intricate twists using fine files and sandpapers.

-

Vernis de pré-placage: The sterling silver pendant is polished to a flawless, brise miroir. Cette étape est cruciale, as any scratch or imperfection on the silver will be visible through the gold layer.

-

Phase 5: The Vermeil Plating Process

The polished silver pendants undergo the transformative plating process.

8. Nettoyage à ultrasons: Pendants are thoroughly cleaned to remove all polishing compounds and oils.

9. Rinçage: Multiple rinses in deionized water ensure absolute purity.

10. Électroplaste:

* The pendants are mounted on a rack that conducts electricity.

* The rack is immersed in an electrolyte solution containing ions of rose gold (un alliage d'or et de cuivre).

* Un courant électrique est passé par la solution, causing the rose gold ions to bond molecularly to the silver surface.

* The time in the bath is carefully monitored to guarantee the plating thickness meets or exceeds the 2.5-micron Vermeil standard.

11. Final Rinse and Anti-Tarnish Treatment: The plated pendants are rinsed and often treated with a protective sealant to delay tarnishing and enhance durability.

Phase 6: Contrôle de qualité rigoureux

Every single pendant is subjected to a rigorous inspection.

-

Test d'épaisseur: A sample from the batch is tested with an X-ray Fluorescence (Xrf) tester to verify the gold thickness.

-

Inspection visuelle: Under high-powered magnification, inspectors check for plating consistency, color uniformity, surface defects, and the quality of the finish on the complex twist design.

-

Functionality Check: If the pendant has a bail (the loop that holds the chain), it is checked for size and smoothness.

Phase 7: Assemblée, Conditionnement, et livraison

-

Production en chaîne: The chosen chain style is manufactured and plated to the same Vermeil rose gold standard in-house.

-

Assemblée: The finished twist cross pendant is attached to the chain via its bail.

-

QC final: The complete necklace is inspected for overall appearance, fonction de fermoir, et longueur.

-

Emballage de marque: The necklace is packaged in the client’s specified packaging—be it a simple pouch or a custom-branded box.

-

Expédition: The order is securely packed and shipped to the client’s destination, with all necessary documentation.

Iv. L'avantage de jinging: Au-delà de la fabrication

Partnering with JINGYING offers brands tangible strategic benefits:

-

Rentabilité: Eliminates massive capital investment in equipment and specialized labor.

-

Vitesse de marché: Streamlined processes from CAD to delivery ensure faster turnaround times.

-

Évolutivité: Effortlessly manage orders from small batches to large-scale production.

-

Conseils d'experts: Leverage JINGYING’s technical expertise to optimize designs for cost, durabilité, and aesthetics.

-

Assurance qualité: Build your brand’s reputation on consistently high-quality products.

V. Conclusion: Forging Lasting Value through Partnership

The creation of a Fashion Twist Cross Pendant Necklace in Vermeil Rose Gold is a perfect case study in modern jewelry manufacturing. It demonstrates how a symbol of tradition can be reimagined through contemporary design and premium materials to create a product with lasting appeal.

Pour une marque, the choice of an OEM partner is one of the most critical decisions they will make. Jinging, with its blend of advanced technology, master craftsmanship, and a client-centric partnership model, provides more than just manufacturing—it provides the foundation for brand growth and success. By entrusting JINGYING with the production of such a detailed and quality-dependent piece, brands can focus on what they do best: commercialisation, narration, and building connections with their customers, confident that the product they deliver is nothing short of exceptional.