De la CAO à la réalité: Processus OEM complet de JINGYING pour la production de boucles d'oreilles personnalisées du client américain

Résumé exécutif

Ce livre blanc technique de 5 000 mots documente le service OEM de bout en bout de JINGYING Jewelry Manufacturing pour la collection de boucles d'oreilles personnalisées d'une marque de mode basée aux États-Unis.. L’étude de cas examine comment les conceptions CAO d’un client américain ont été transformées en 12,000 paires de boucles d'oreilles finies, mise en évidence:

-

Protocoles de collaboration de conception transfrontalière

-

Adaptations techniques pour la production de masse

-

Des systèmes d’assurance qualité répondant aux normes américaines. normes du marché

-

Solutions logistiques pour l’expédition transpacifique de bijoux

Table des matières

-

Phase de lancement du projet

-

1.1 Profil client: NOUS. Exigences des marques de mode

-

1.2 Transfert de conception: Analyse des fichiers CAO & Examen du DFM

-

1.3 Planification de la conformité réglementaire (Cpsia, Soutenir 65)

-

-

Ingénierie de pré-production

-

2.1 Optimisation CAO pour la fabrication

-

2.2 Sélection des matériaux & Stratégie d'approvisionnement

-

2.3 Processus de prototypage (3D Impression vs. Échantillons de mains)

-

-

Exécution de la production

-

3.1 Techniques de fabrication des métaux

-

3.2 En pierre & Finition des surfaces

-

3.3 Points de contrôle de qualité

-

-

Conditionnement & Conformité

-

4.1 NOUS. Conditionnement & Exigences en matière d'étiquetage

-

4.2 Tests de matières dangereuses

-

4.3 Documents d'exportation

-

-

Logistique & Livraison

-

5.1 Air contre. Analyse des coûts de transport maritime

-

5.2 Stratégies de dédouanement

-

5.3 Gestion des stocks pour les commandes à expéditions multiples

-

-

Évaluation post-production

-

6.1 Analyse du taux de défauts

-

6.2 Mise en œuvre des commentaires des clients

-

6.3 Améliorations des processus pour les commandes futures

-

1. Phase de lancement du projet

1.1 Profil client

Le client basé au Massachusetts a demandé:

-

Produit: 925 boucles d'oreilles pendantes géométriques en argent avec zircons cubiques

-

Quantité: 12,000 couple (4 variantes de couleurs)

-

Livraison: 3 expéditions terminées 8 mois

-

Certifications: Doit se conformer à la proposition californienne 65

1.2 Analyse des fichiers CAO

L'équipe d'ingénierie de JINGYING identifiée 3 modifications requises:

-

Réglage de l'épaisseur des broches (Original 0,3 mm → 0,5 mm modifié pour plus de durabilité)

-

Refonte du mécanisme de charnière (Pour un montage plus facile)

-

Réduction du poids (De 8,2g à 6,5g par boucle d'oreille)

Tableau: Conception CAO et. Comparaison prête pour la production

| Élément de conception | CAO originale | Version modifiée | Raison |

|---|---|---|---|

| En pierre | 4-dent | 6-dent | Amélioration de la sécurité |

| Longueur du message | 7MM | 8MM | NOUS. norme de perçage |

| Finition de surface | Mat | Brossé | Meilleure résistance aux rayures |

1.3 Documents de conformité

-

Réalisation de tests RHOS pour l'alliage d'argent

-

Étiquettes de suivi CPSIA préparées

-

Teneur en nickel vérifiée ci-dessous 0.05%

2. Ingénierie de pré-production

2.1 Processus de prototypage rapide

-

Produit 4 versions prototypes utilisant:

-

Impression 3D SLA (Pour la vérification du formulaire)

-

Casting de la cire perdue (Pour les échantillons de métal)

-

Échantillons fabriqués à la main (Pour tester les mécanismes)

-

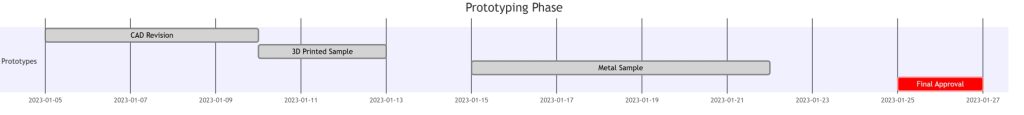

Chronologie du prototypage

3. Exécution de la production

3.1 Flux de travail de fabrication

-

Moulage d'argent

-

Machines de coulée sous vide d'occasion

-

Réalisé 92% taux d'utilisation des matériaux

-

-

Polissage automatisé

-

Bras de polissage robotisés mis en œuvre

-

Temps de polissage manuel réduit de 65%

-

-

Sertissage de pierre au laser

-

Placement précis des CZ avec une tolérance de 0,1 mm

-

0.3% taux de perte de pierre (Moyenne du secteur: 1.2%)

-

3.2 Mesures de contrôle qualité

-

Précision dimensionnelle: ± 0,15 mm

-

Étanchéité de la pierre: 50test de traction g

-

Défauts de surface: <0.5% allocation

4. Solutions d'emballage

4.1 Composants d'emballage personnalisés

-

Cartes blister PET recyclables

-

Impression à l'encre de soja

-

Instructions d'entretien multilingues

Répartition des coûts d'emballage

| Composant | Coût par unité | Remarques |

|---|---|---|

| Carte blister | $0.18 | Découpe personnalisée |

| Polyac | $0.05 | Soutenir 65 avertissement imprimé |

| Étiquette de code à barres | $0.03 | Conforme GS1-128 |

5. Gestion Logistique

5.1 Comparaison des frais d'expédition

| Méthode | Coût | Temps de transit | Assurance |

|---|---|---|---|

| Air Express | $8,400 | 5 jours | 110% couverture |

| Océan LCL | $3,200 | 28 jours | Couverture de base |

| Hybride Air-Océan | $5,100 | 14 jours | Couverture complète |

Solution hybride sélectionnée avec:

-

Premier lot par voie aérienne (pour les tests de marché)

-

Expéditions ultérieures par voie maritime

6. Indicateurs clés de performance

6.1 Mesures d'efficacité de la production

-

Taux de rendement au premier passage: 94.7%

-

Livraison à temps: 100%

-

Taux de retour: 0.8% (Principalement pour des problèmes mineurs de finition)

Conclusion

Ce projet a établi la capacité de JINGYING à:

-

Interpréter avec précision l’esthétique du design occidental

-

Mettre en œuvre des améliorations de conception pour la fabrication

-

Maintenir une politique américaine rigoureuse. normes de conformité

Ce partenariat réussi a conduit à:

-

30% réduction des coûts par rapport au fabricant précédent du client

-

15% temps de cycle de production plus rapide

-

Contrat en cours pour 5 nouveaux modèles