Del CAD a la realidad: Proceso OEM completo de JINGYING para la producción de aretes personalizados de clientes estadounidenses

Resumen ejecutivo

Este documento técnico de 5000 palabras documenta el servicio OEM integral de JINGYING Jewelry Manufacturing para la colección de aretes personalizados de una marca de moda con sede en EE. UU.. El estudio de caso examina cómo los diseños CAD de un cliente estadounidense se transformaron en 12,000 pares de aretes terminados, destacando:

-

Protocolos de colaboración de diseño transfronterizo

-

Adaptaciones técnicas para la producción en masa.

-

Los sistemas de garantía de calidad se reúnen en EE. UU.. estándares de mercado

-

Soluciones logísticas para el envío de joyas transpacífico

Tabla de contenido

-

Fase de inicio del proyecto

-

1.1 Perfil del cliente: A NOSOTROS. Requisitos de la marca de moda

-

1.2 Traspaso de diseño: Análisis de archivos CAD & Revisión de DFM

-

1.3 Planificación de Cumplimiento Normativo (Cpsia, Apuntalar 65)

-

-

Ingeniería de preproducción

-

2.1 Optimización CAD para la fabricación

-

2.2 Selección de material & Estrategia de abastecimiento

-

2.3 Proceso de creación de prototipos (3D Impresión vs.. Muestras de mano)

-

-

Ejecución de producción

-

3.1 Técnicas de fabricación de metales

-

3.2 Puro de piedra & Acabado superficial

-

3.3 Puntos de control de calidad

-

-

Embalaje & Cumplimiento

-

4.1 A NOSOTROS. Embalaje & Requisitos de etiquetado

-

4.2 Pruebas de materiales peligrosos

-

4.3 Documentación de exportación

-

-

Logística & Entrega

-

5.1 Aire vs.. Análisis de costos de envío marítimo

-

5.2 Estrategias de despacho de aduanas

-

5.3 Gestión de inventario para pedidos de envíos múltiples

-

-

Evaluación de postproducción

-

6.1 Análisis de tasa de defectos

-

6.2 Implementación de comentarios de clientes

-

6.3 Mejoras de procesos para pedidos futuros

-

1. Fase de inicio del proyecto

1.1 Perfil del cliente

El cliente con sede en Massachusetts solicitó:

-

Producto: 925 Pendientes colgantes geométricos de plata con circonitas.

-

Cantidad: 12,000 pares (4 variantes de color)

-

Entrega: 3 envíos sobre 8 meses

-

Certificaciones: Debe cumplir con la Proposición de California 65

1.2 Análisis de archivos CAD

El equipo de ingeniería de JINGYING identificado 3 modificaciones requeridas:

-

Ajuste del grosor de las puntas (Original 0,3 mm → Modificado 0,5 mm para mayor durabilidad)

-

Rediseño del mecanismo de bisagra (Para un montaje más fácil)

-

Reducción de peso (De 8,2 ga 6,5 g por pendiente)

Mesa: Diseño CAD frente a. Comparación lista para producción

| Elemento de diseño | CAD originales | Versión modificada | Razón |

|---|---|---|---|

| Puro de piedra | 4-diente | 6-diente | Mejora de la seguridad |

| Longitud de la publicación | 7mm | 8mm | A NOSOTROS. estándar de perforación |

| Acabado superficial | Mate | Cepillado | Mejor resistencia al rayado |

1.3 Documentación de cumplimiento

-

Se realizaron pruebas de RHOS para aleaciones de plata.

-

Etiquetas de seguimiento CPSIA preparadas

-

Contenido de níquel verificado a continuación 0.05%

2. Ingeniería de preproducción

2.1 Proceso rápido de creación de prototipos

-

Producido 4 versiones prototipo usando:

-

Impresión 3D SLA (Para verificación de formulario)

-

Casting de cera perdido (Para muestras de metales)

-

Muestras hechas a mano (Para pruebas de mecanismos)

-

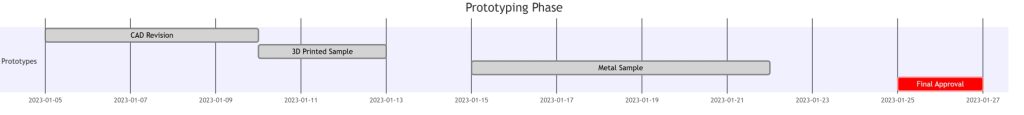

Cronología de creación de prototipos

3. Ejecución de producción

3.1 Flujo de trabajo de fabricación

-

Fundición de plata

-

Máquinas de colada al vacío usadas

-

Logrado 92% tasa de utilización de materiales

-

-

Pulido automatizado

-

Brazos de pulido robóticos implementados

-

Reducción del tiempo de pulido manual mediante 65%

-

-

Ajuste de piedra láser

-

Colocación precisa de CZ con tolerancia de 0,1 mm.

-

0.3% tasa de pérdida de cálculos (Promedio de la industria: 1.2%)

-

3.2 Métricas de control de calidad

-

Precisión dimensional: ±0,15 mm

-

Estanqueidad de la piedra: 50prueba de tracción g

-

Defectos superficiales: <0.5% prestación

4. Soluciones de embalaje

4.1 Componentes de embalaje personalizados

-

Tarjetas blister de PET reciclables

-

Impresión con tinta a base de soja

-

Instrucciones de cuidado multilingües

Desglose de costos de embalaje

| Componente | Costo por unidad | Notas |

|---|---|---|

| Tarjeta Blíster | $0.18 | Troquelado personalizado |

| Bolsa de polietileno | $0.05 | Apuntalar 65 advertencia impresa |

| Etiqueta de código de barras | $0.03 | Cumple con GS1-128 |

5. Gestión Logística

5.1 Comparación de costos de envío

| Método | Costo | Tiempo de tránsito | Seguro |

|---|---|---|---|

| Air Express | $8,400 | 5 días | 110% cobertura |

| Océano LCL | $3,200 | 28 días | Cobertura básica |

| Híbrido Aire-Océano | $5,100 | 14 días | Cobertura total |

Solución híbrida seleccionada con:

-

Primer lote vía aérea (para pruebas de mercado)

-

Envíos posteriores vía marítima

6. Indicadores clave de desempeño

6.1 Métricas de eficiencia de producción

-

Tasa de rendimiento del primer paso: 94.7%

-

Entrega a tiempo: 100%

-

Tasa de retorno: 0.8% (Principalmente por problemas menores de acabado.)

Conclusión

Este proyecto estableció la capacidad de JINGYING para:

-

Interpretar con precisión la estética del diseño occidental.

-

Implementar mejoras de diseño para fabricación.

-

Mantener rigurosos EE.UU.. normas de cumplimiento

La exitosa asociación ha llevado a:

-

30% Reducción de costos versus el fabricante anterior del cliente.

-

15% tiempo de ciclo de producción más rápido

-

contrato en curso para 5 nuevos diseños